Uncategorised

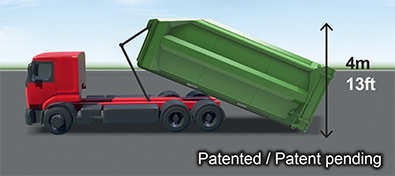

All the MetroTaifun vital components and systems are protected with more than 500 patent applications worldwide.

All trademarks are registrated worldwide

Developing the world’s most advanced Automatic Waste Collection System AWCS for sustainable environment!

MariMatic® has over 30 years of experience in pipe waste collection systems, having already supplied almost 1,000 systems in more than 40 countries and in regard to MetroTaifun®, we hold an extensive portfolio of patents and patent applications in Finland and abroad. We have invested millions of euros in research and development of the MetroTaifun® Automatic solid Waste collection System (AWCS), and thanks to our activities, MariMatic has become a pioneer in its sector. We expect to be the global market leader in this field.

To continue the development and research, we have built a MetroTaifun Technology and Demo Center, which is recognized for having the world’s largest working demonstration Automatic Solid Waste Collection System (AWCS) completely installed indoors. For those visiting the center, it is conveniently located just some 30 minutes from Helsinki-Vantaa airport.

The original office building has been expanded and the center was completed in summer 2012. This has enabled continued and unrestricted product development and testing of the MetroTaifun system in its entirety. The extensive area now available offers excellent opportunities for training and adequate space for demonstrating the function and features of the complete Automatic Solid Waste Collection System. The company’s training center, auditorium and offices will be integrated into the center, which has an area of 3400 m2 (36,597 sq. ft.).

The Test and Demo Equipment on display consists of approximately 2000 meters of interconnected composite and steel piping with 19 fully functioning waste inlets of various designs and sizes. All possible waste inlet designs for indoor and outdoor use in the various MetroTaifun installations are demonstrated a long with the different gravity chute and AWCS solutions.

The overview of the layout with 2400 m of piping.

At the end of the pipe network installation, there is a complete waste terminal equipment assembly, including blowers, air filtration, compactors, and the accompanying control software and hardware.

Waste cyclone, dust cyclone and waste container set up

To give a realistic understanding of the waste separation procedure possibilities, there are three (i.e., waste fractions) systems installed at the different waste inlet stations for separating the waste. This demonstrates how the conveying air is used to transport the different fractions separately and gives a clear idea of the potential for developing many various waste handling scenarios the customer may need.

The panoramic overview from a waste inlet platform makes it is easy to see how the MetroTaifun Waste Collection System functions

The smart technology hidden below ground makes it possible for the waste inlets to operate smoothly

Welcome to visit our demo center in Järvenpää, Finland!

Contact info(@)marimatic.com

Waste transfer station in Vuores, Tampere, Finland

|

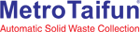

Waste station 1. Waste separation cyclone |

Smart waste station 1. Integrated waste separation |

The development of the compact MT-Waste Transfer Station enables the buildings to be smaller, saving costs for both valuable land and the building. The advanced innovations in MetroTaifun® technology also reduce the necessary waste conveying airflow, sound- and odour level as well as the energy consumption to a third, enabling smaller equipment to be used.

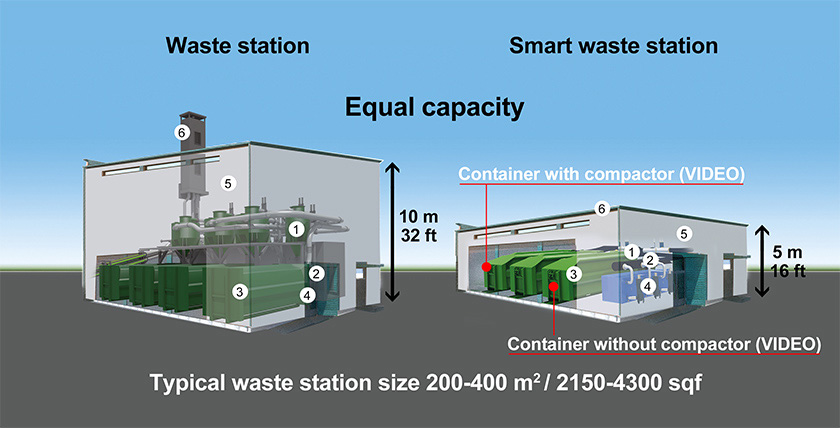

Waste is conveyed via an underground pipe network from MT-Waste collection stations (inlets) to a central MT-Waste transfer station, where the waste is separated from the conveying air. The waste is automatically distributed to separate waste containers for each fraction. The spoiler front shape of the MT-Containers reduces the height in the waste transfer station when tilted. The fuel consumption is also reduced by 10% during truck transport.